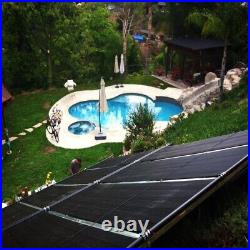

Solar Pool Heater SunHeater S120U Universal 2 X 20-Feet Black Simple DIY Install. 240 x 27 x 3 inches. Simple DIY installation; for in ground or above ground pools. Installs on roof, rack, ground or fence. Patented web design for maximum exposure to sun’s rays. Uses existing pool pump. Raises pool water temperature 6-10 degrees F. Additional kits or plumbing may be required. A Sun Heater solar heating system is the, cost effective way to warm your pool. Capture free heat from the sun’s rays to raise your water temperature 6-10 degrees F! Can add weeks to you pool season. Universal system is suitable for both in ground or above ground pools. We offer the best prices around on high quality products. Our E-store includes media such as books, movies, music and games while offering electronics, toys, sporting apparel, clothing, tools, general home, garden items and more. We are always working hard to ensure your package arrives as soon as possible. We do not accept P. Please provide a physical address. We try our very best to make sure every customer is completely satisfied. If there’s a problem, message us! We’re happy to help.

Hayward W3H150FDN Universal H-Series 150,000 BTU Natural Gas Pool and Spa Heater for In-Ground Pools and Spas!

This unit is brand-new and has been removed from the box. It was sitting outside for 6 months without use so it shows signs of cosmetic wear.

SunHeater S120U Universal Solar Pool Heater 2 by 20-Feet Black 2 x 20 SunHeater S120U Universal Solar Pool Heater 2 by 20-Feet Black 2 x 20.

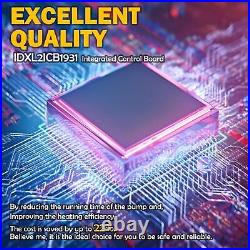

IDXL2ICB1931 Integrated Control Board for Hayward Universal H-Series Low Nox IDL. For Hayward replacement part? IDXL2ICB1931 Integrated Control Board fits for Hayward H-Series Low Nox Induced Draft (IDL / IDL2). H250IDL1, H250IDL2, H250IDPL1, H250IDPL2, H300IDL1, H300IDL2, H300IDPL1, H300IDPL2, H400IDL1, H400IDL2, H400IDPL1, H400IDPL2. If your old Hayward bathtub has been used for many years, the control module has a heating failure. It is recommended that you replace it directly. This product meets or exceeds OEM specifications and has been factory tested. Old parts can be replaced directly, safe and reliable, and stable performance! Efficient and safe operation? Without any other complicated settings, the temperature of the 850 gallon swimming pool can rise by 35 degrees in less than an hour. By reducing the running time of the pump and improving the heating efficiency, the cost is saved by up to 22%. Believe me, it is the ideal choice for you to be safe and reliable. IDXL2ICB1931 integrated control board is made of the latest upgraded materials, with stable performance and excellent moisture resistance. Reliable use and longer service life. It is more convenient to use and install. Note: For swimming pool and spa heaters manufactured after September 2004. Your satisfaction is our top priority, We strive to provide customers with quality services. Locate the 120 VAC VoltageSelector Plug and install it into the receptacle. All wiring connections to the heater must be made in accor-dance with the latest edition of the National Electrical CodeANSI/NFPA 70, unless local code requirements specify oth-erwise. In Canada, follow csA C22.1-CANADIAN ELEc-TRICAL CODE, Part 1. The heater must be electrically grounded and bonded inaccordance with local codes, or in the absence of localcodes, with National Electrical Code, ANSI/NFPAA 70. The H-Series heater must be installed with the electricalconnections, service entry/remote control, located on theleft side of the heater. Field wiring connections are to be made to the Fuse Boardbehind the control access panel. Connect the field supplywires to the terminal block on the Fuse Board. Connect theground wire to the lug adjacent to the Fuse Board. Tightenterminal screws to 8 in-lbs. If you are not satisfied for any reasons, please do not be so quick to leave negative/neutral feedback.

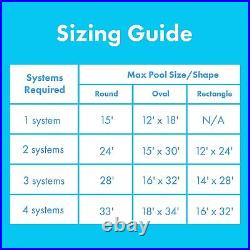

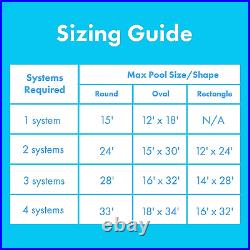

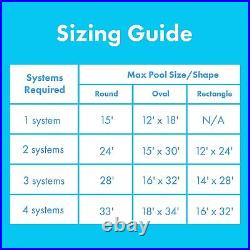

SwimEasy solar panels are the perfect choice for anyone looking to replace an existing. That uses rubber hoses & metal hose clamps. Is also a great choice for those looking for a premium panel without the premium price tag. This panel has been used by installers across the country for decades for one simple reason; it works, and keeps on working. Each panel is built from high-grade materials proven to last in all types of weather and deliver a life expectancy of 15-20 years. Each panel is manufactured from precompounded polypropylene with synergistic antioxidants and UV screen including carbon black. These special additives play a vital role in developing a panel capable of withstanding the harsh conditions of a rooftop, in all types of weather, for many years to come. Each panel is put up against more than 40 quality control inspections throughout the entire manufacturing process to ensure the final product. STATE OF THE ART MANUFACTURING. SwimEasy solar panels undergo a state-of-the-art manufacturing process designed to significantly increase the materials resistance to UV light. This process eliminates the inherent quality issues that plague cheaply manufactured products which typically see a lifespan of only 1-2 years. “Not All Plastic Is Created Equal”. For details on the quality differences between the two primary types of resin blends. A rooftop is a harsh environment and it is not easy to produce a collector capable of withstanding its conditions for a sustained period of time, see why below. SwimEasy collectors are constructed in a “tube-and-web” design which separates each individual round tube by a thin strip or “web”. This design allows for normal expansion and contraction that occurs due to thermal heating and cooling, extending life expectancy. Each panel is comprised of 8 individual plates that are thermally-welded and insert-molded. A direct, metered manifold delivers a balanced flow through the collector and prevents hot-spots. SwimEasy solar panels fit interchangeably with any solar pool heater panel featuring a round 1.5″ or 2″ I. Header manifold and makes connections with a rubber hose type connector. The header size is a measurement of the. PLEASE VERIFY THIS SIZE BEFORE ORDERING. This is a common mistake easily avoided. NOT ALL PLASTIC IS CREATED EQUAL. Unmodified polypropylene has a high rate of degradation from UV exposure. Sunlight breaks down the plastic and weakens it, a serious problem for a solar collector as its very nature is to collect as much sunlight as possible. Each absorber plate of a SwimEasy solar collector is made from a propylene copolymer with synergistic antioxidants and UV screen including carbon black. These special additives, coupled with state-of-the art manufacturing techniques, substantially increase the material’s resistance to UV light. These are vital components toward creating a collector able to withstand the harsh conditions of a roof-top for years to come. Products made from plastic typically start out as one-of-two types of resin blends. Masterbatch: Natural (clear) resin pellets are mixed with a concentrate during the extrusion process. This concentrate would contain additives and fillers used to affect the end-product’s physical appearance or properties. Precompounded: Compounding is a process of melt-blending plastics with other additives. This process alters the physical, thermal, or aesthetic characteristics of the plastic. Compounding starts with a base resin, which is blended with additives in an industrial mixer, producing a final resin ready for use in manufacturing. Additives are evenly distributed throughout the resin and subsequent end-products. The Ideal Choice if Your Looking For.. > A SIMPLE INSTALLATION. SwimEasy utilizes rubber couplings and metal hose clamps to make connections. These components are by far the fastest & simplest method for attaching & securing a solar pool heating system. They offer far more wiggle room during installation than propriety clamp style systems (less hassle & faster assembly). > RELIABILITY & LONGEVITY. State-of-the-art manufacturing coupled with special additives merge to create a panel capable of withstanding the harsh conditions of a rooftop, in all types of weather, for up to 15-20 years. Constructed of 8 individual plates that are thermally-welded and insert-molded. A tube-and-web design separates each individual round tube by a thin strip or “web”. This design allows for normal expansion and contraction while collecting more heat. Made from precompounded polypropylene, a process which increases the materials resistance to UV light (lengthens service life substantially). This manufacturing process eliminates the inherent quality issues that plague cheaply manufactured products which typically see a lifespan of only 1-2 years. > REPLACEMENT SOLAR PANEL. SwimEasy solar panels will replace any solar pool heater that has a round 1.5″ or 2″ I. The header size is a measurement of the internal diameter. Please verify this size before ordering. (1) SwimEasy Solar Pool Heater Panel. SAVE BIG ON MULTI PANEL ORDERS! Looking for multiple panels? Installing a complete replacement system or a new one for the first time? Be sure to check out our selection of DIY KITS. These products are bundled together with significant discounts, saving you up to. Each of our DIY Kits include everything you need to. Install the selected number of solar panels in a single row or “bank”. Mount each solar panel to your preferred installation surface (roof or rack). Make water connections to and from each panel. Make water connections to the systems’ supply and return plumbing lines. Aid in automatic gravity drainage of the panels and piping. WHAT SIZE SYSTEM DO I NEED? The most relevant aspect of sizing a system is based on the square footage of your pool. We typically recommend matching anywhere from 50%-100% of your pools total surface area to solar collector coverage (solar panels). For example, if your pool is 500 square feet, then 50% solar coverage equals 250 square feet of solar panels, 75% solar coverage equals 375 square feet of solar panels, etc. From this point, you’ll want to look at selecting a panel size that fits your installation area. For a complete breakdown on how to select & size the right solar pool heating system, see our sizing help page. SIZING GUIDE: How Many Panels?

Hayward W3H150FDP Universal H-Series 150,000 BTU Propane Pool and Spa Heater. BEST FOR: In-ground pools and spas with a surface area up to 400 ft. Where natural gas is available. Its low environmental impact makes it ideal for pools and spas located where low-NOx emissions are required. PREMIUM PERFORMANCE: The Hayward Universal H-Series 150,000 BTU Propane Heater delivers premium heating performance for years of reliable, long-lasting comfort. CORROSION PROTECTION: The Universal H-Series boasts exceptional protection against corrosion and premature failure caused by unbalanced water chemistry. ENERGY SAVINGS: The efficient, industry-leading design reduces circulation pump run time to provide energy savings. EASY-TO-USE: Intuitive front control panel provides easy operation, service and maintenance. The Universal H-Series 150,000 BTU Propane Gas Pool & Spa Heater from Hayward provides reliable, long-lasting comfort for pools and spas with a surface area of up to 400 ft. Built with a durable cupro nickel heat exchanger, it offers exceptional protection against corrosion and premature failure caused by unbalanced water chemistry, ensuring season after season of premium heating performance. The Universal H-Series boasts industry-leading hydraulic performance coupled with lightning-fast speed-to-heat capability- so you spend less time waiting, and more time swimming. Its low NOx emissions meet air quality standards in all low-NOx areas, so you can rest easy knowing its environmental impact is low, too.

Yoursme FDXLICB1930 FD Integrated Control Board Replacement Kit for Hayward Universal H-Series Low Nox Pool Heater Models H250FDN, H250FDP, H300FDN, H300FDP, H350FDN, H350FDP, H400FDN, H400FDP. Universal Fitment –This FDXLICB1930 FD Integrated Control Board is universal for Hayward H-Series Low Nox Pool Heater Models H250FDN H250FDP H300FDN H300FDP H350FDN H350FDP H400FDN H400FDP. Run Your Heater Again — If your heater has given you an error code of CE, it is likely time for a new Integrated Control board. On some occasions, an error code of HF can also indicate a problem with this part. This integrated control board replacement kit makes it easy to replace the integrated control board and get your heater running again quickly. High Standard — This is a high standard after market replacement kit, the main board is made of FR-2 Copper Clad Laminate, all the Japan made capacitors with high precision welding tech effectively avoid short circuit and burn down. Three anti-paint coated for excellent insulation, moisture resistance, salt water and corrosion Resistance. Technical Specifications — Comes with all-inclusive kit contains all parts to replace the Integrated Control Board. Multiple adapters on board for managing and controlling all powered heater functions. Replace OEM part number FDXLICB1930, Catalog Part Number: 6223-175. Dimensions 5.57″ x 4.33″.